CNC Lathes Models 1236 & 1340

» Proven performer! More than twice the machining speed of our nearest competitor.

» Reliable! In production for more than a decade with many customers who come back and purchase more machines as their needs grow.

» Guaranteed. Five year warranty on electronics, free software updates, and expert technical support.

» Includes the stands, many accessories, and professional skidding on pallets. (Crating for export available for extra charge).

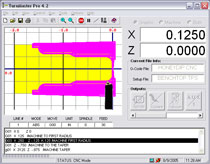

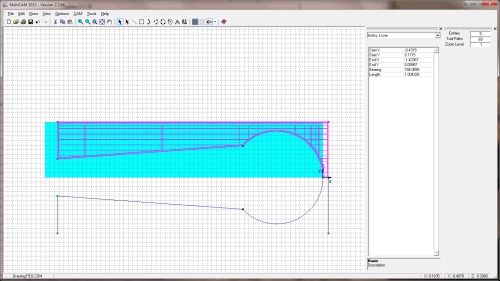

The CNC Lathe Models 1236 and 1340 are well proven CNC turning machines that have established themselves for 10+ years to be of unprecedented value in prototyping, tool making, tensile test parts sampling, and small to medium production. With 300+ machines delivered in USA and world wide of this model (1236 &1340) and several thousand tabletop lathes delivered by MicroKinetics of all models, the company has demonstrated experience to deliver value and quality for a quarter of century. Advanced CNC machining on a lathe using a standard PC or laptop is now affordable and a pleasure to use with all the latest enhancements of high performance USB based motion control and the continual development of the amazing TurnMaster Pro master control software. Now featuring automatic wizards for threading, roughing of tapers and arcs, and feeds and speeds selections for a variety of common materials. What's more, the VFD option now allows constant surface speeds for great surface finish as well as high performance parting/cut-off operations. With the availability of the automatic tool post and turret support, these lathes can have the capability that rival many of the more expensive production CNC lathes.

Download/Print Product Brochure

-

High Speeds

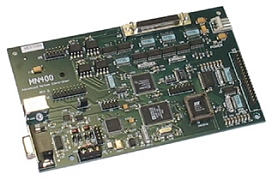

- The latest technology constant current chopping drives used in the DriveRack power electronics result in very high feed and rapid rates, while the MN400 motion controller insures maximum reliability with the use of opto-isolated inputs and outputs on ALL connections. Other systems may use direct connection or a printer port whose reliability is not acceptable for industrial applications.

-

Low Cost Accessories

-

Since our CNC machines are designed around existing manual machines, they accept standard tools and accessories. This means you won't have to spend a fortune on specialized or custom tooling. The most commonly needed ones are included with the package for convenience and added savings. We offer a full assortment of low cost tools and accessories.

-

Quality

-

MicroKinetics CNC systems are expertly built and performance tested to conform to stringent standards. Detailed assembly and testing procedures and checklists are followed to insure consistent, repeatable, high quality. All components are individually tested and the complete system is tested again as a unit before shipment.

-

Industry Leader

-

MicroKinetics offers the best reasonably priced CNC systems and knowledgeable technical support in the industry. Five year warranty on electronics and one year warranty on mechanics. MicroKinetics has been offering CNC systems to educational institutions, hobbyists, research facilities and small machine shops since 1985 using the same business philosophy, expert engineering and technical support!

SPECIFICATIONS:

| Parameter | Model 1236 |

Model 1340 |

| Swing Over Bed | 12" |

13" |

| Swing Over Gap | 17" |

18

3/4 " |

| Length of Gap | 9" |

7

7/8" |

| Swing Over Cross-Slide | 7½" |

8" |

| Swing Over Compound | 3" |

3" |

| Distance Between Centers | 36" |

40 " |

| Carriage Travel | 30" |

35 1/4" |

| Cross-Slide Travel | 6" |

6

7/8 " |

| Compound Travel | 2

5/8" |

2

5/8" |

| Tailstock Spindle Travel | 3

5/8" |

3

3/4 " |

| Tailstock Taper | 3

MT |

3

MT |

| Spindle Nose Mounting | D1-4 |

D1-4 |

| Spindle Bore Diameter | 1½" |

1½" |

| Spindle Taper | 5

MT |

5

MT |

| Spindle Taper with Sleeve | 3

MT |

3

MT |

| Spindle Speeds (Number) Range | (9)

70 - 1400 |

(8)

70 - 2000 |

| Motor & Electrics | 2

HP, 220V, single phase |

2

HP, 220V, single phase |

| Machine Net Weight | 1100 lbs |

1200 lbs |

| Machine Gross Weight | 1200 lbs |

1300 lbs |

| Controller Gross Weight | 75 lbs |

75 lbs |

| Machine Dimensions W/O Stand | 22"H

x 26"W x 60"L |

30"H

x 33"W x 73"L |

| Floor Space Required - Max. | 30"W

x 70"L |

36"W

x 73"L |

-

FEATURES:

-

- Geared head with splash oil lubrication

- Easy change 9 Speeds and infinitely variable speeds with VFD

- Powerful 2 HP motor, 1 phase, 220 Volt D1-4 spindle

- Hardened and ground bed with reinforced cross ribs

- Headstock with tapered roller bearings

- Electromagnetic starter switch

- Large spindle bore diameter

- High speed machining

-

ELECTRONICS & SOFTWARE: -

-

The electronics, and software are our half stepping high power 80 volt DriveRack system (2 axis) with TurnMaster Pro software and the MN400 motion controller. The motors are 34HT1275 and 34HT750.

-

SYSTEM INCLUDES:

-

- CNC Lathe Model 1236 or 1340

- Stepper Motors: (1) 750 oz-in (1) 1275 oz-in

- DriveRack 2-Axis 80V F/H

- MN400 Advanced Motion Controller

- TurnMaster Pro G-code control & graphical software

- Limit switches, cables, stand, chip pan and technical manuals

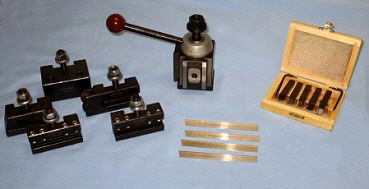

- Also included are the following pictured accessories:

3 MT Dead Center

8" 4-Jaw Chuck

10" Faceplate

Steady-rest

Follow-rest

6" 3-Jaw Chuck

1 1/16" Capacity 4-way Toolpost

Toolbox with Tools

999-1236-010 Collet Closer for 1236

999-1340-010 Collet Closer for 1340

999-6500-010 Flood Coolant System complete with all needed accessories

999-1236-200 Quick Change Tooling Package

999-1236-003 Boring Bar Set

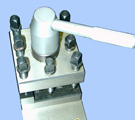

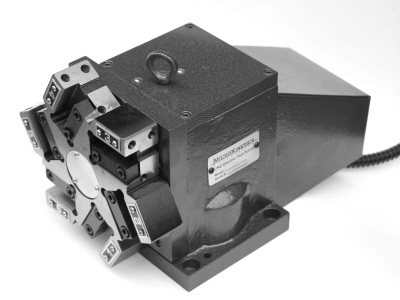

NEW 999-1236-460 Automatic Tool Turret 6 Station

(3 phase power not required)

>999-1236-450 AT6-1236 Tool Change Riser Kit

999-1236-455 AT6-1340 Tool Change Riser Kit

999-1236-461 Round Tool Holder for AT6

999-1236-462 Square Tool Holder for AT6

NEW 999-1236-440 Automatic Tool Post 4 Station

(3 phase power not required)

999-1236-430 AT4-1236 Tool Change Riser Kit

999-1236-435 AT4-1340 Tool Change Riser Kit

900-0200-201 Round Tool Adapter for AT4

900-0200-111 ER16 Straight Shank 5/8 Chuck

999-1236-050 Variable Speed Spindle

900-0200-001 ER16 Precision Collet 9 Pc Set (Imperial 1/8" to 3/8")

900-0200-002 ER16 Precision Collet 10 Pc Set (Metric 1mm to 10mm)

999-1236-040 Lathe Splash Guard Lexan

900-0200-013 18 Piece 5C Collet Set

900-0095-054 Turning Tool Set 5/8

999-1236-041 Front Splash Guard Kit

Sample Parts

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The following items are included with a system. They are listed here for re-ordering or purchasing extras.

Product |

Item # |

Price |

Order |

|

|

|

|

|

|

|

|

|

|

|

Prices updated 03/28/2025