Mid-size Conversion Kits

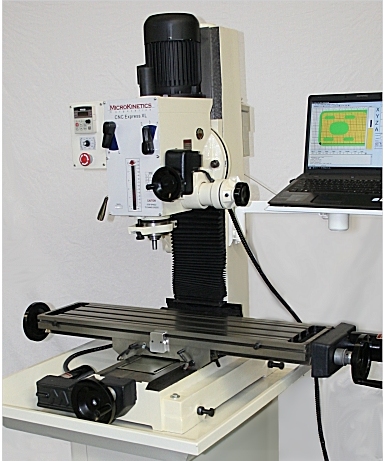

Rong Fu/Enco/Grizzly Stand Type CNC Mill Kit

Offering impressive machining power, repeatability, and convenience, the CNC Express Conversion Kit is available as a complete retrofit kit ready to install on your own manual Rong Fu RF31,RF45, Enco, Grizzly or similar mill/drill. If you enjoy building projects, you can save money and have fun building your own CNC Express CNC milling machine. With this kit installed, you'll be able to machine complex shapes that would otherwise be impossible and you'll be able to repeat the process achieving perfect duplicate parts with very little effort and mostly unattended operation.

The custom made, precision ballscrews on the X and Y axes offer accurate circular and contour cuts without the tedious setup of a rotary table. Additionally, increased machining performance and improved tool life are realized by utilizing climb milling operations not possible with standard lead screws.

The kit includes step-by-step, illustrated assembly instructions to make the whole process easy and fun.

The kit includes pre-wired stepper motors, motor mounting plates with covers, ballscrews, pulleys, belts, limit switches, and all mounting bolts. In addition to the above components, this package also includes MillMaster Pro for Windows G-code interpreter and graphical simulation software, the DriveRack electronics with built-in MN400 USB controller. All cabling and manuals are included... all you supply is the base mill, a low cost computer, and your labor. Just bolt everything on, make a few adjustments and you're up and running in less time than with any other system. Also for your convenience, we offer a suitable base machine at a discounted price when purchased with this kit.

Accessories for this kit are available on the factory built page shown here.

KIT INCLUDES:

- 5TPI (.200") ballscrews at .003" per foot max linear error

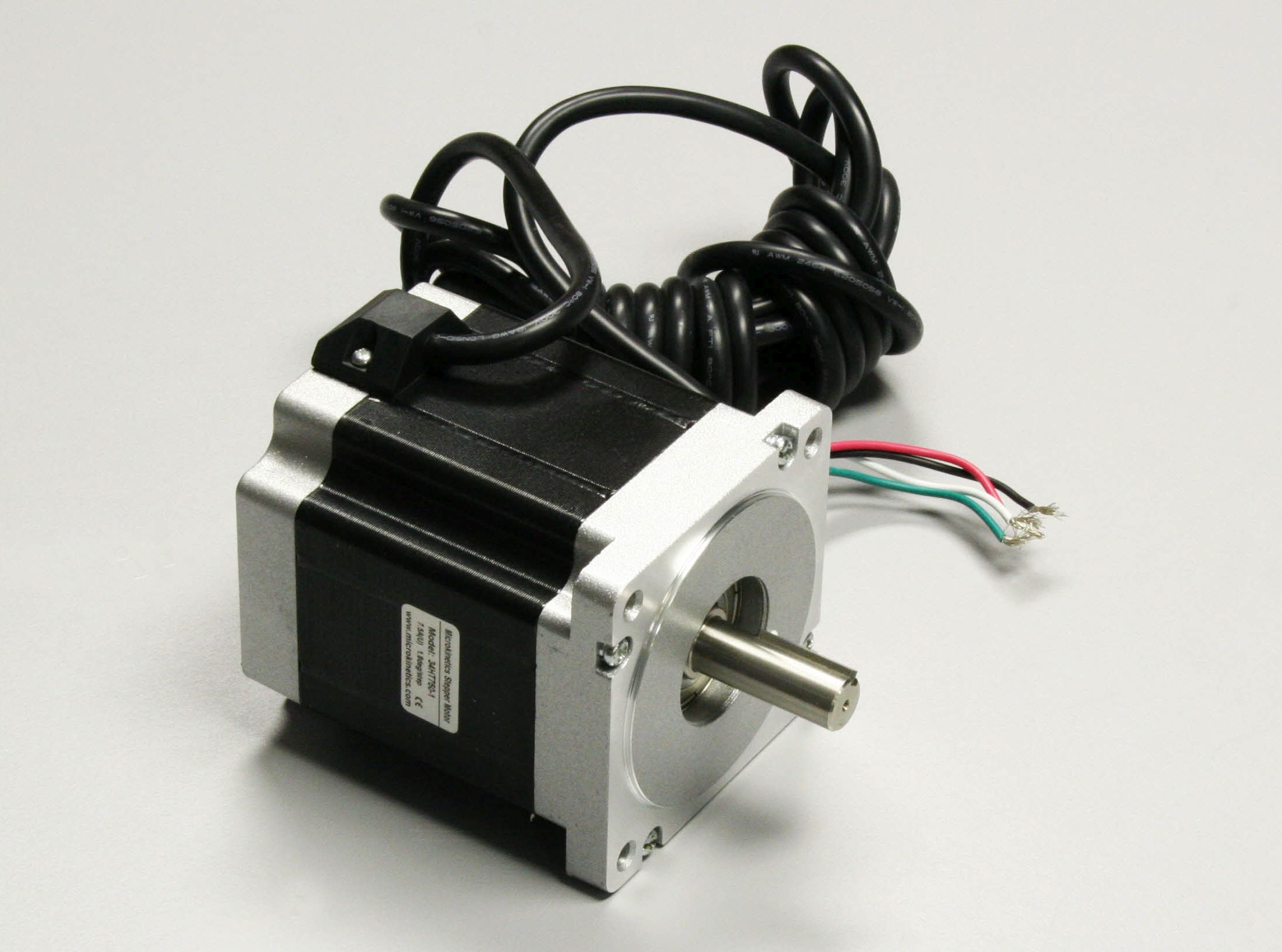

- Stepper motors (2) 34HT750 (1) 23HT350

- DriveRack high performance power driver

- Built-in Motionet MN400 Continuous contouring motion controller

- MillMaster Pro for Windows G-code control & graphical software

- Limit switches, cables, technical manuals, and a CNC Express serial # plate

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CNC Lathe 1236 Conversion Kit

The CNC Lathe 1236 Conversion Kit is available as a complete retrofit kit ready to install on your own manual Enco, Birmingham, Jet, Nova, Grizzly, or similar 12" X 36" lathe. The kit offers ample machining power, repeatability, and convenience, With this kit installed, you'll be able to use single point cutting tools to eliminate the need for form tooling and the need for the oprator to actively perform all the operations by hand. You'll be able to call up a part program and machine perfect duplicate parts. The custom made precision ballscrews on both the X and Z axes allow precision taper and curved cuts without the setup of a compound slide. And with the electronic threading option you’ll be able to make infinitely variable internal, external, single or multistart as well as tapered (pipe) threads.

All mechanical components are precision engineered and the kit include step-by-step, illustrated instructions.

The kit includes pre-wired stepper motors, motor mounting plates with covers, ballscrews, pulleys, belts, limit switches, and all mounting bolts. In addition to the above components, this package also includes TurnMaster Pro for Windows G-code interpreter and graphical simulation software, and the DriveRack electronics with built-in MN400 USB controller. All cabling and manuals are included... all you supply is the basic 12" x 36" lathe and a suitable desktop or laptop computer. We also offer a suitable base lathe (if you don't already have one) at a discounted price when purchased with this kit.

Accessories for this kit are available on the factory built page shown here.

KIT INCLUDES:

- 5TPI (.200") ballscrews at .003" per foot max linear error

- Stepper motors (1) 34HT750 (1) 34HT1275

- DriveRack high performance power driver

- Built-in Motionet MN400 Continuous contouring motion controller

- TurnMaster Pro for Windows G-code control & graphical software

- Limit switches, cables, technical manuals, and a CNC 1236 serial # plate

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CNC Lathe 1340 Conversion Kit

The CNC Lathe 1340 Conversion Kit is available as a complete retrofit kit ready to install on your own manual Enco, Birmingham, Jet, Nova, Grizzly, or similar 13" X 40" lathe. The kit offers ample machining power, repeatability, and convenience, With this kit installed, you'll be able to use single point cutting tools to eliminate the need for form tooling and the need for the oprator to actively perform all the operations by hand. You'll be able to call up a part program and machine perfect duplicate parts. The custom made precision ballscrews on both the X and Z axes allow precision taper and curved cuts without the setup of a compound slide. And with the electronic threading option you’ll be able to make infinitely variable internal, external, single or multistart as well as tapered (pipe) threads.

All mechanical components are precision engineered and include step-by-step, illustrated instructions.

The kit includes pre-wired stepper motors, motor mounting plates with covers, ballscrews, pulleys, belts, limit switches, and all mounting bolts. In addition to the above components, this package also includes TurnMaster Pro for Windows G-code interpreter and graphical simulation software, and the DriveRack electronics with built-in MN400 USB controller. All cabling and manuals are included... all you supply is the basic 13" x 40" lathe and a suitable desktop or laptop computer. We also offer a suitable base lathe (if you don't already have one) at a discounted price when purchased with this kit.

Accessories for this kit are available on the factory built page shown here.

KIT INCLUDES:

- 5TPI (.200") ballscrews at .003" per foot max linear error

- Stepper motors (1) 34HT750 (1) 34HT1275

- DriveRack high performance power driver

- Built-in Motionet MN400 Continuous contouring motion controller

- TurnMaster Pro for Windows G-code control & graphical software

- Limit switches, cables, technical manuals, and a CNC 1340 serial # plate

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Lathe Motor Assemblies (optional)

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Variable Spindle Speed Kit for Mill or Lathe

The Variable Spindle Speed kit includes the cabinet that mounts to the mill (999-6500-040) or the parts kit for the lathe (999-1236-055), a 2 HP VFD, emergency stop, variable speed control and electronic display as well as the necessary mounting hardware.

Threading Kit

The threading kit includes the threading encoder, cable, pulleys, and mounting hardware.

|

|

|

|

|

|

|

|

|

|

|