Industrial CNC

Rotary Tables

6", 8", and 10" Models

This

series of high precision, stepper motor driven, vertical/horizontal rotary tables can be used with a milling machine

to produce complex parts with great accuracy. The rotary "A" axis

is supported by our MillMaster Pro and is commanded in degrees. The standard

resolution using half stepping results in 100 discrete postions per degree

(or 0.005 degrees/step). The stepper motor is the 34HT390 rated at 6.6

Amps per phase and includes prewired, armor jacketed cables with a circular locking Amp connector.

FEATURES:

- 90:1 Gear Ratio;

0.005°/Step

- Horizontal and

vertical mounting

- Morse taper

center hole

- T-Slots and extra

deep coolant channels

- Industrial quality armor jacketed 10 foot long cable

- IP65 splash protected entry

- Matching tailstock

available

| Standard

Speed Range |

0.1

- 4.6 RPM |

| Resolution

|

0.005°

|

| Flatness

of Clamping Surface (concave) |

0.0006" |

| Concentricity

of Center Bore |

0.0008" |

| Parallelism

of Clamping Surface to Angle Face |

0.0008" |

| Squareness

of Angle Surface to Clamping Surface |

0.0004" |

| Squareness

of Clamping Surface to Center Slot |

0.0008" |

|

Part#

|

900-0095-006

|

900-0095-008

|

900-0095-013

|

|

|

6” Table

|

8” Table

|

10” Table

|

|

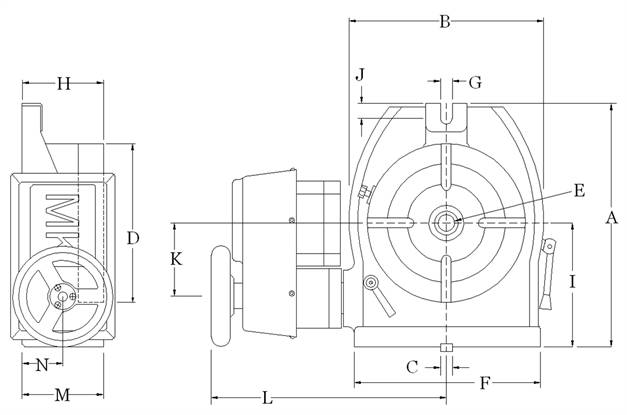

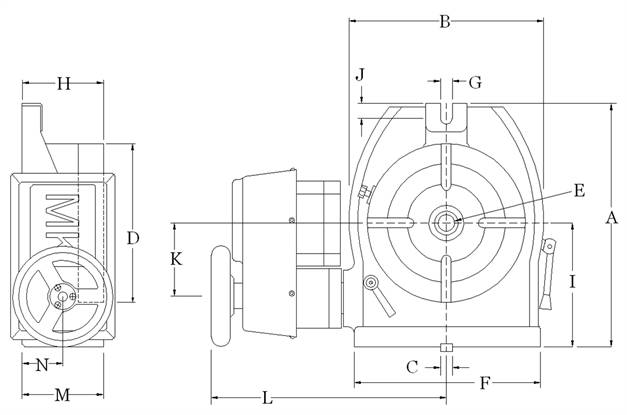

A

|

9.53

|

11.20

|

12.90

|

|

B

|

7.72

|

9.40

|

11.30

|

|

C

|

0.472

|

0.552

|

0.650

|

|

D

|

6.296

|

7.782

|

9.800

|

|

E

|

2MT

|

3MT

|

3MT

|

|

F

|

7.320

|

8.204

|

9.960

|

|

G

|

0.472

|

0.570

|

.562

|

|

H

|

3.350

|

3.944

|

4.330

|

|

I

|

4.920

|

5.985

|

6.750

|

|

J

|

0.47

|

0.61

|

0.63

|

|

K

|

3.0

|

3.7

|

4.1

|

|

L

|

9.351

|

12.181

|

13.003

|

|

M

|

3.230

|

3.880

|

4.175

|

|

N

|

1.46

|

1.90

|

1.90

|

|

T-Slots

|

0.390

|

0.465

|

0.465

|

MOTOR ELECTRICAL POWER CONNECTOR:

|

4 pin female circular connector-front view

cable length - 10' standard |

Product

|

Order #

|

Price

|

Order

|

|

|

$

|

|

|

|

$

|

|

|

|

$

|

|

|

|

$

|

|

| |

|

|

|

|

|

$

|

|

|

|

$

|

|

|

|

$

|

|

|

|

$

|

|

| |

|

|

|

|

|

$

|

|

|

|

$

|

|

4 Jaw Chuck Kit for 10-in Rotary Table

|

Coming

|

Soon

|

|

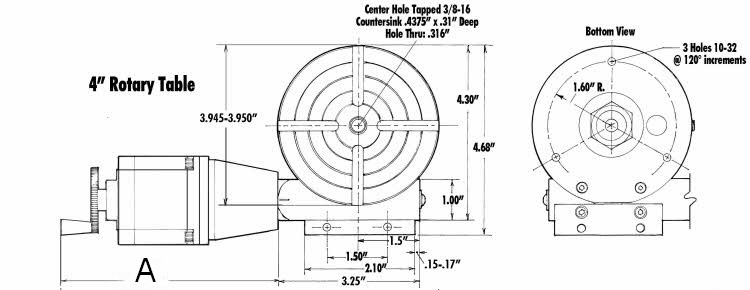

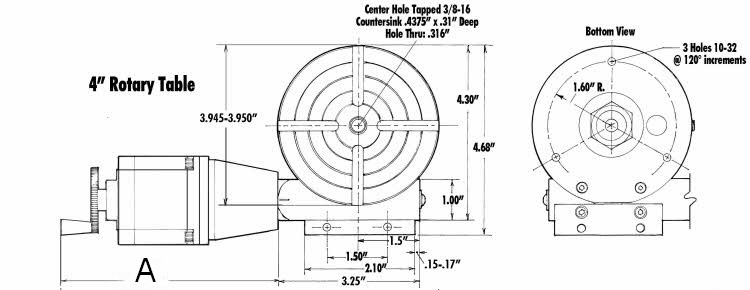

Mini CNC

Rotary Table and Accessories

4" Model

___

___

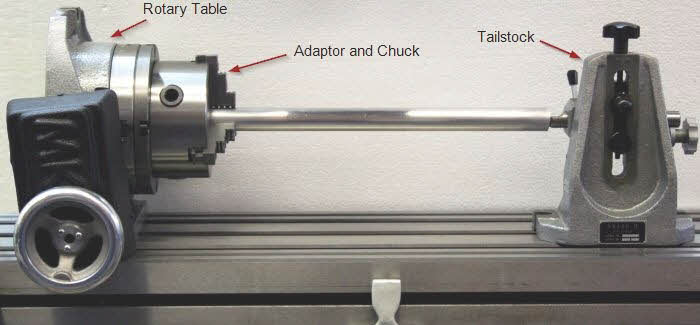

This high precision,

stepper motor driven rotary table can be used with a mill and MillMaster

Pro software allowing a machinist to produce complex parts

with precision. The rotary "A" axis is supported by MillMaster

Pro and is commanded in degrees. The standard resolution using half stepping results in 80 positions

per degree (or 0.0125 deg per step).

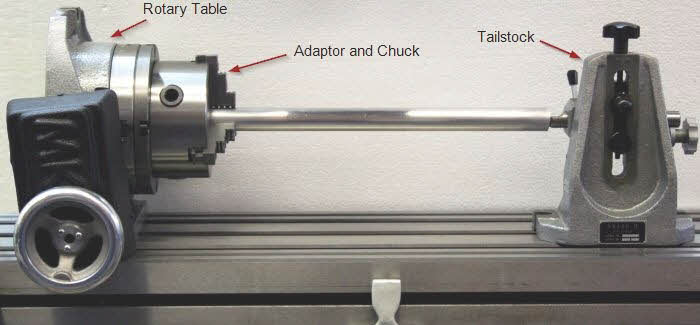

The rotary table can fasten directly to themill bed using standard

hold down set (included) or it can be used with the optional vertical

mount, part # 870-3701-000 and/or tailstock part #

870-3702-000 for working on longer parts between centers. Additionally a self-centering 3-Jaw chuck Part# 870-1041-000

as well as a independent type 4-jaw chuck part# 870-1042-000 are available. There are additional accessories also available as shown below.

MOTOR ELECTRICAL POWER CONNECTOR:

Order #

|

Description

|

Motor Model

|

Torque

|

"A" Dimension

|

Connector

|

|

|

|

23HT350D |

350 oz.in |

5.68" |

|

|

|

|

23HT175D |

175 oz.in |

4.45" |

|

|

Four-jaw

chucks have four advantages over three-jaw chucks. 1) They can be used

to hold irregularly shaped parts. 2) With the use of a dial indicator,

they can be used to center parts with great accuracy. 3) Four-jaw chucks

can be used to deliberately hold a part off-center. 4) They can clamp

stock tighter. This is a valuable asset when machining cams, crankshafts,

and similar parts. The main disadvantage of the 4-jaw independent chuck

is that the jaws must be individually set, adding extra time to setups.

Like the 3-jaw chucks, 4-jaw chucks can be used to clamp either externally

or internally. This 2.5" (63mm) 4-jaw chuck is designed to grip

from 3/32" (2mm) up to 1-3/16" (30mm) diameter stock with

the jaws in the normal position. For larger diameters, the jaws are

reversed to grip up to 2-1/4" (56mm). The chuck has a .687"

(17mm) through hole with a 3/4-16 thread. A hex key is used to tighten

each jaw individually. Tommy bars (provided) are used in the holes in

the side to tighten and loosen the chuck for more leverage. A groove

is around the base of the chuck so that angle clamps can be used to

mount it to the table of a mill as a holding fixture.

|

|

This

compact chuck is a good all-around workhorse for most lathe work.

It has a clamping range of from 3/32" (2 mm) up to 1-3/16"

(30 mm) diameter with the jaws in the normal position. With the jaws

in the reversed position, work up to 2-1/4" (56 mm) can be gripped.

The hole through the chuck is .687" (17 mm). Rotating the knurled

ring closes all three jaws simultaneously to quickly grip round or

hexagonal stock. Tommy bars (provided) are used in the holes in the

side to tighten and loosen the chuck for more leverage. The chuck

has a 3/4-16 thread to fit the spindle on the lathe or mill.

|

|

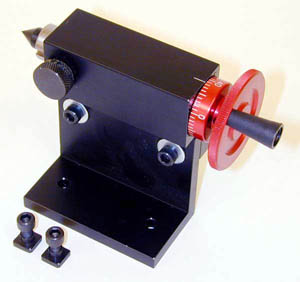

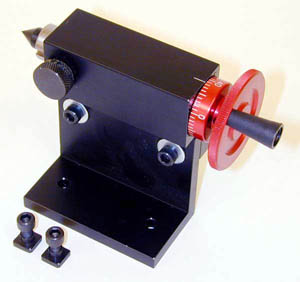

Designed to easily mount the Rotary Table on a vertical plane and maintain rigidity.

|

|

Mounts on mill table and is adjustable to allow for perfect alignment between the rotary table and the tailstock while holding long parts between centers.

|

|

The center is ball bearing mounted so that it can rotate with the part, reducing wear and heat.

|

|

Used in the Headstock to drive wood when turning between centers. It is a simple and direct method which takes less time to set up than using a 3 Jaw Chuck.

|

|

Allows chucks with a 3/4-16 spindle thread to be mounted to the tailstock for holding tools or work

|

|

Allows

you to attach the 3-Jaw chuck to the rotary table so that you can

hold round pieces.

|

Product

|

Order #

|

Price

|

Order

|

|

|

$

|

|

|

|

$

|

|

|

|

$

|

|

|

|

$

|

|

|

|

$

|

|

|

|

$

|

|

|

|

$

|

|

|

|

$

|

|

|

|

$

|

|

|

|

$

|

|

|