MillMaster Pro™

The easiest to use CNC Master control software for milling, routing and plasma cutting machines

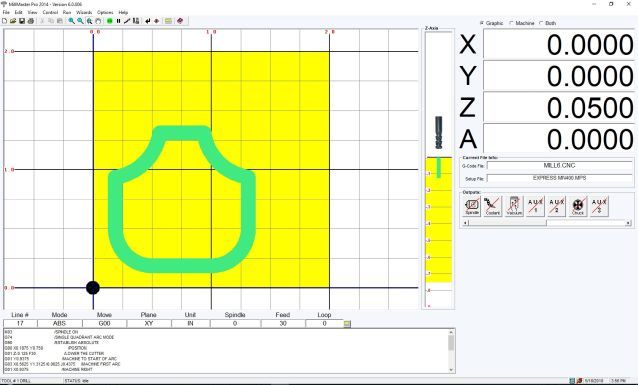

MillMaster Pro for Windows controls and graphically simulates 3-axis milling operations on a PC. The CNC part program can be typed directly into the editor screen, or can be generated via a CAD/CAM program. The interactive mode allows you to see the operation performed graphically as you type each CNC line, aiding in part program development or training. For documentation purposes, you can print the graphics screen and the part program together or separately. True circular interpolation on any two axes and simultaneous linear interpolation on all axes are standard. This allows full 3-D surfacing designs to be run on the target 3 axis machine. Also supports 4th axis operation.

Features

- Large X,Y,Z, & A axis coordinate display

- Outputs and machine status display

- Full color animated graphics with true tool diameter depiction for clearances

- RS274D standard G & M codes

- Capacity for very long part programs as generated by CAD/CAM software

- Backlash compensation

- Includes lettering subroutine library

- Easy tool jogging from keyboard

- External speed control for wire EDM

- Supports subroutines/macros and global variables

- Has canned cycles including drilling, boring, and deep profiling

- Graphically simulates all tool movements and cutting operations

- Includes a full screen text editor

- Supports metric and inch programming

Familiar Windows Style Menus

Menu & Toolbar System

With an easy to use interface including:

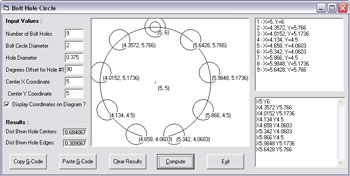

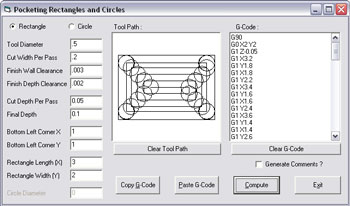

- Built in CNC Assist Tools which make common complex operations easy

- Bolt Hole Circle

- Pocketing

- Speeds and Feeds Calculator

- Bolt Hole Circle

- Decision making and branching based on variable/parameter value

- New syntax checking routine helps you correct common errors in your part programs

- Advanced Continuous Contouring

- Compatibility with Windows 8.1 and 10

Industry Standard G & M Codes

Preparatory Functions (G-Codes)

G00 Rapid positioning moveG01 Linear cutting move

G02 Clockwise circular cutting move

G03 Counterclockwise circular cutting move

G04 Set dwell in seconds

G17 Select the XY plane for contouring (default)

G18 Select the XZ plane for contouring

G19 Select the YZ plane for contouring

G25 Execute subroutine

G26 Conditional branch

G27 Unconditional branch

G28 Set system or user defined variable to value

G70 Set inch programming (default)

G71 Set metric programming

G72 Set rotary table scaling

G74 Set single quadrant arc mode (default)

G75 Set multiple quadrant arc mode G77 Canned cycle for milling a channel along the X axis

G78 Canned cycle for milling a channel along the Y axis

G79 Canned cycle for milling a deep channel

G80 Cancel canned cycle

G81 Canned cycle for drilling a hole

G82 Canned cycle for spot facing

G83 Canned cycle for deep hole drilling

G85 Canned boring cycle

G87 Canned drilling cycle with chip break

G89 Canned boring cycle with dwell

G90 Set absolute programming mode

G91 Set incremental programming mode (default)

G92 Set current tool position counters to value

Miscellaneous Functions (M-Codes)

M00 Temporary stopM02 End of program stop

M03 Spindle on CW (output #1)

M04 Spindle on CCW (output #5)

M05 Spindle off (output#1, output#5)

M06 Tool change

M08 Coolant on (output #2)

M09 Coolant off (output #2)

M10 Vacuum on (output #3)

M11 Vacuum off (output #3)

M12 Auxiliary Output on (output #4)

M13 Auxiliary Output off (output #4)

M17 Return from subroutine

M25 Rapid traverse to home position

M39 Chuck close (output #6)

M40 Chuck open (output #6)

M94 Issue Controller literal command

M97 Wait for true input state then continue

M99 Restart part program from beginning

Special Codes

* Multiplies two values/variables

\ Divides two values/variables

+ Adds two values/variables

-Subtracts two values/variables

A Rotary table angle

F Feedrate

S Spindle speed

T Tool number

V Rotary table velocity

Quality

MicroKinetics CNC software packages are expertly designed and tested to conform to stringent standards. Detailed testing procedures and checklists are followed to insure consistent, repeatable, high quality finished product.

|

|

|

|

|

|

|

New low price! |

|

|

|

|

New low price! |

|

|

Prices updated 03/28/2025